Part of Tranquil Mount Ltd, First floor, Swan Buildings, 20 Swan Street, Manchester M4 5JW

Rockpanel Sleeves: Fix-Point-Sleeve II & Drift Punch Tool for Secure Installation

24

04Rockpanel Sleeves: Fix-Point-Sleeve II & Drift Punch Tool for Secure Installation

Rockpanel Sleeves: Secure & Flexible Panel Installation

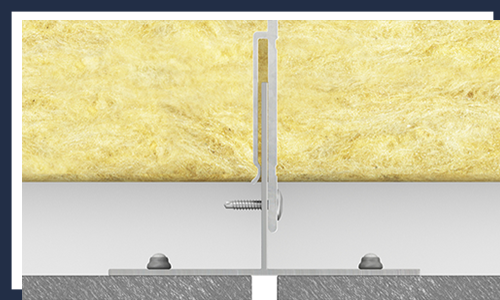

Rockpanel sleeves play a crucial role in façade panel installation, ensuring secure fixation while allowing for necessary movement due to thermal expansion and structural shifts. These sleeves, commonly referred to as Fix-Point-Sleeves, are designed to maintain the integrity and durability of Rockpanel cladding systems.

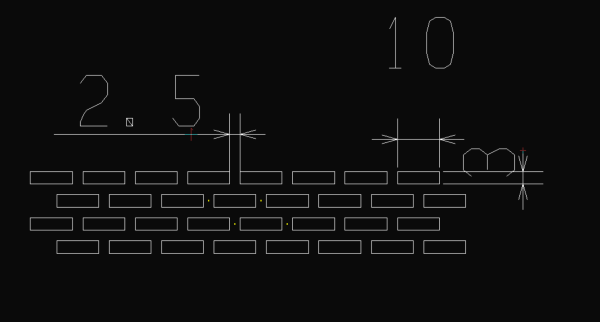

Fix-Point-Sleeve II Aluminium Ø 8 mm with Slotted Hole 5.1 x 6.2 mm, Length 7.5 mm

The Fix-Point-Sleeve II is an aluminium sleeve with an 8 mm diameter and a length of 7.5 mm. Its 5.1 x 6.2 mm slotted hole allows for slight movement of façade panels, reducing stress and preventing cracks or structural damage. This makes it an essential component for ensuring a long-lasting and secure Rockpanel installation.

Drift Punch Tool for Fix-Point-Sleeve II Installation

To install the Fix-Point-Sleeve II correctly, a Drift Punch Tool is used to position the sleeve accurately into pre-drilled holes. This tool ensures precision during the installation process, guaranteeing that the sleeve is properly seated for optimal performance. Using the correct tool helps maintain the flexibility and durability of the façade system.

Why Use Fix-Point-Sleeves?

- Prevents Panel Damage: Allows for controlled expansion and contraction.

- Ensures Secure Fixation: Keeps panels firmly in place while reducing stress.

- Long-Term Durability: Minimizes risks of cracking or distortion over time.

- Easy Installation: Designed for straightforward fitting with the Drift Punch Tool.

For professionals working with Rockpanel cladding, Fix-Point-Sleeves and the Drift Punch Tool are essential components that ensure a secure, flexible, and long-lasting installation.